We might be producing concrete that is 30 % stronger by processing and including charred espresso grounds to the combo, researchers in Australia found.

Their intelligent recipe may resolve a number of issues on the identical time.

Yearly the world produces a staggering 10 billion kilograms (22 billion kilos) of espresso waste globally. Most leads to landfills.

“The disposal of organic waste poses an environmental challenge as it emits large amounts of greenhouse gases including methane and carbon dioxide, which contribute to climate change,” defined RMIT College engineer Rajeev Roychand.

With a booming building market globally, there’s additionally an ever growing demand for useful resource intensive concrete inflicting one other set of environmental challenges too.

“The ongoing extraction of natural sand around the world – typically taken from river beds and banks – to meet the rapidly growing demands of the construction industry has a big impact on the environment,” mentioned RMIT engineer Jie Li.

“There are critical and long-lasting challenges in maintaining a sustainable supply of sand due to the finite nature of resources and the environmental impacts of sand mining. With a circular-economy approach, we could keep organic waste out of landfill and also better preserve our natural resources like sand.”

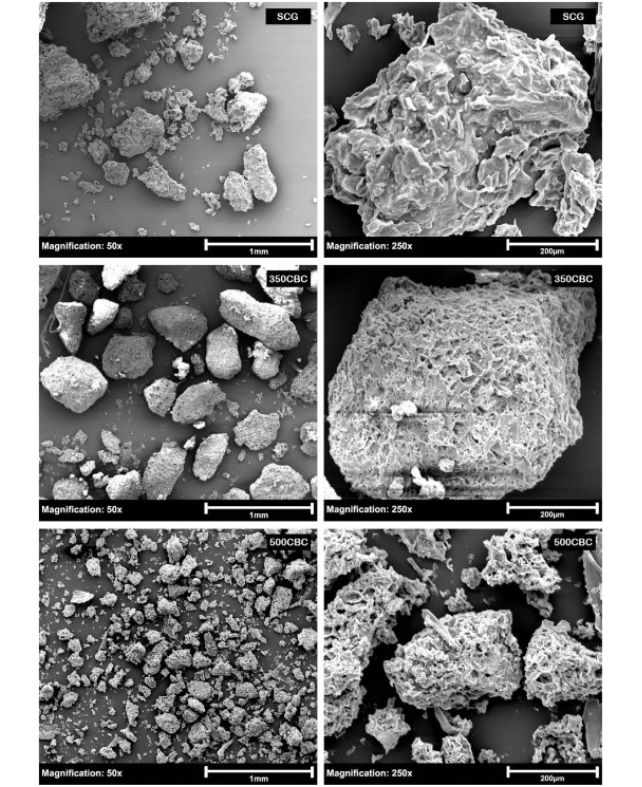

Natural merchandise like espresso grounds cannot be added on to concrete as a result of they leak chemical substances that weaken the constructing materials’s energy. So utilizing low power ranges the workforce heated espresso waste to over 350 °C (round 660 °F) whereas depriving it of oxygen.

This course of known as pyrolyzing. It breaks down the natural molecules, leading to a porous, carbon-rich charcoal known as biochar, that may type bonds with and thereby incorporate itself into the cement matrix.

Roychand and colleagues additionally tried pyrolyzing the espresso grounds at 500 °C however the ensuing biochar particles weren’t as robust.

The researchers cautioned that they nonetheless must assess the long run sturdiness of their cement product. They’re now engaged on testing how the hybrid coffee-cement performs underneath freeze/thaw cycles, water absorption, abrasions and plenty of extra stressors.

The workforce can also be engaged on creating biochars from different natural waste sources, together with wooden, meals waste and agricultural waste.

“Our research is in the early stages, but these exciting findings offer an innovative way to greatly reduce the amount of organic waste that goes to landfill,” mentioned RMIT engineer Shannon Kilmartin-Lynch.

“Inspiration for my research, from an Indigenous perspective, involves Caring for Country, ensuring there’s a sustainable life cycle for all materials and avoiding things going into landfill to minimize the impact on the environment.”

Their analysis was printed within the Journal of Cleaner Manufacturing.

An earlier model of this text was printed in September 2023.