Our reliance on plastic has develop into an enormous drawback, which is why researchers are excited a couple of new kind of fabric – one which comes with built-in biodegrading capabilities, because of the bacterial spores residing inside it.

The brand new self-digesting plastic combines thermoplastic polyurethane (TPU) and Bacillus subtilis micro organism, which needed to be engineered to outlive the excessive temperatures concerned in plastic manufacturing.

By repeatedly exposing the spores to growing ranges of warmth, the crew of researchers behind this new work discovered that the micro organism might ultimately deal with the temperatures of 135 levels Celsius (275 levels Fahrenheit) required to combine the bacterial spores and TPU collectively.

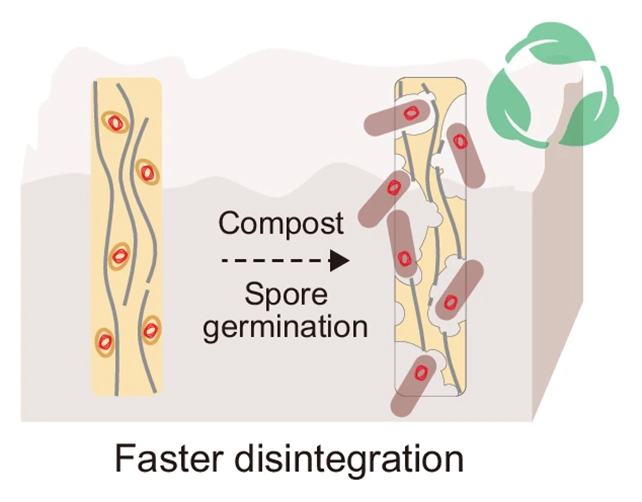

Previous efforts to search out methods to degrade plastics, quick, have usually sourced bacterial enzymes and fungi from soils and compost heaps the place these microbes are naturally considerable. However this new materials wants solely the bacterial spores inside it, reawakened with some vitamins and moisture, to begin breaking down.

“What’s remarkable is that our material breaks down even without the presence of additional microbes,” says Jon Pokorski, a polymer scientist on the College of San Diego (UC San Diego) who led the crew.

“Chances are, most of these plastics will likely not end up in microbially rich composting facilities. So this ability to self-degrade in a microbe-free environment makes our technology more versatile.”

The analysis concerned a number of vital levels, beginning with selecting B. subtilis. It is a kind of micro organism that has beforehand been linked to the breaking down of plastic, and it could actually survive in a dormant state with out the same old provides of meals and vitality.

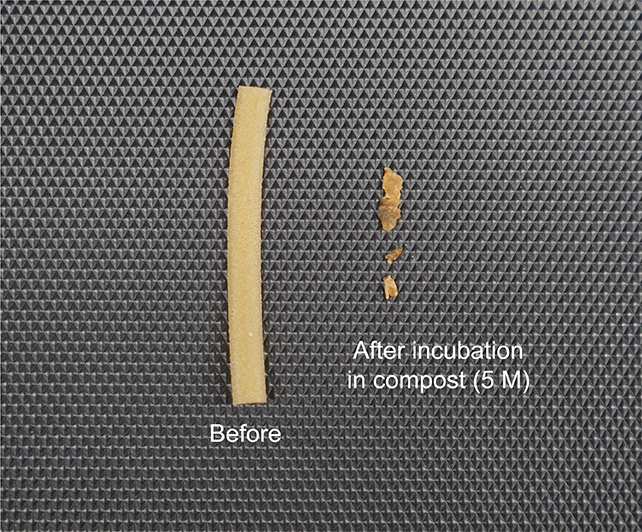

One other stage was testing the decomposition price of the brand new plastic: In splendid composting circumstances, which reawakened the micro organism from their dormant state, 90 p.c of the plastic had disappeared in 5 months. There have been optimistic indicators that some stage of degradation might happen in much less splendid circumstances too.

This could possibly be key relating to disposing of such a plastic, if it have been to be commercially developed. Analysis reveals that not all ‘compostable’ plastics break down as marketed.

What’s extra, along with making the plastic biodegradable, the researchers additionally discovered the micro organism spores made the fabric some 30 p.c stronger, in addition to including to its stretchability.

“Both of these properties are greatly improved just by adding the spores,” says Pokorski. “This is great because the addition of spores pushes the mechanical properties beyond known limitations where there was previously a trade-off between tensile strength and stretchability.”

TPU is used extensively in all types of merchandise, from telephone instances to automobile components, however there’s presently no efficient approach of recycling it. As plastic manufacturing will increase at a fast price, we’re in pressing want of the way to restrict how a lot of it will get dumped within the surroundings.

There’s loads of scope for future analysis right here: from ensuring that the micro organism left behind after decomposition is innocent, to experimenting with totally different combos of plastics and micro organism, and scaling up the entire course of.

Different researchers are in the meantime making an attempt to make plastics that aren’t comprised of fossil fuels similar to crude oil or their derivatives.

“There are many different kinds of commercial plastics that end up in the environment – TPU is just one of them,” says Adam Feist, a bioengineer at UC San Diego.

“One of our next steps is to broaden the scope of biodegradable materials we can make with this technology.”

The analysis has been printed in Nature Communications.